There are a lot of the modern asset tracking technologies that you can use for tracking field and office assets. You can use barcodes (regular UPC barcodes or QR codes), blutooth (BLE beacon tags), NFC, RFID or GPS tags. These asset tracking technologies have very different price tags, initial setup requirements, asset tracking equipment and user involvement in the asset tracking process. What is the best technology to use for the asset tracking? It depends on the assets, your use case and your budget. In this articles we tried to highlight the most important information on each asset tracking technology and show business scenarios where it works best. Using this data you will be able to design the best asset management strategy and select the best asset tracking technology for your specific situation.

Here is a very short overview of the differences between the various asset tracking technologies:

- Barcode vs QR code for asset tracking These are almost the same technologies, that require minimal investment in the initial asset management system setup, the least ongoing costs and require an employee to scan a barcode or QR code label to track assets. QR code is easier for the smartphones to read and it can encode more information, so with everything else being equal QR code may be preferable.

- Barcode / QR code vs NFC for asset tracking. NFC asset tracking requires slightly higher initial investment as compared to barcode / QR code assets tracking. The benefits of NFC assets tracking are faster processing of the assets transactions, and an ability to process assets transactions when NFC tag is not visible (e.g. inside the casing or packaging). You need to touch NFC tag with a smartphone in order to scan it, while for scanning QR codes or barcodes you need to bring up and focus a smartphone camera.

- Bluetooth (BLE beacons) vs RFID or NFC for asset tracking. Bluetooth low energy (BLE) is another technology that uses radio waves for identifying and tracking assets. Bluetooth asset tracking is very similar to RFID in the capabilities, but requires significantly lower investment. Unlike RFID, bluetooth (BLE) tags can be read by the regular smartphones and tablets and do not require special scanning hardware.

- NFC vs RFID for asset tracking.NFC and RFID are similar technologies that use radio waves to detect and identify the object. The difference is that NFC requires much shorter distance between the asset and a scanner - typically up to an inch. Various RFID tags has different scanning range, which can be from tens of meters to a mile. As a result, in order to track assets with NFC tags, you should scan each asset individually. For the assets with RFID tags, a reader can scan multiple assets instantly at a distance. RFID can also be used for automated continuous mapping of the assets in the limited space (e.g. equipment in the yard or cars on the parking lot).

- Barcode / QR code vs RF technologies (NFC, BLE, RFID) for the asset tracking. RF technologies (NFC, RFID, BLE) have much more capabilities than barcodes / QR codes - they allow for much faster scanning and processing assets transactions, with BLE and RFID allowing for bulk scanning of the assets at a distance and real time assets mapping in the limited space. RF technologies are also more expensive, and for many asset management use cases barcode / QR code option is adequate.

- RFID and BLE vs GPS for asset tracking.GPS is different from the other asset tracking technologies - it provides the real time asset mapping without any human participation and with no limits in space. It is most expensive technology and as a rule is used on the most valuable company assets that are moved large distances (car fleet, construction equipment, shipping containers). GPS can be used only for tracking outdoor assets. RFID and BLE can also be used for the real time assets mapping, inside and outside, but only within the limited space. Unlike GPS, BLE and RFID require receives / gateways for the real time assets mapping.

- Barcode and QR code vs GPS for asset tracking. Barcode and QR code asset tracking is very different from GPS asset tracking. Barcode asset tracking works by the employees scanning a barcode label on each asset and processing an asset transaction. An asset transaction tells the asset management system where the asset was taken from and where it has been moved. GPS asset tracking produces real time map of the asset location and does not require any human participation. However, if GPS asset tracking is outside your budget, you can track GPS loation of the assets by scanning QR code / barcode with a smartphone. After each scan, a smartphone will obtain GPS location of the scan and send to the cloud server for the asset mapping.

Bluetooth Asset Tracking

RFID Asset Tracking

NFC Asset Tracking

GPS Asset Tracking

Asset Tracking Technologies: Takeaways

Barcode Asset Tracking, QR Code Asset Tracking

Traditional UPC (Universal Product Code) barcode is 1D (one-dimensional) barcode that has been in use for a while. QR code (Quick Response Code) is a 2D (two-dimensional) barcode that recently became popular due to its ability to encode large amount of data. When talking about asset tracking, both UPC and QR codes serve the same purpose -- to uniquely identify an asset when it is scanned. Barcodes and QR codes are very similar in terms of labels and tags printing, scanning equipment to use, cost involved and business scenarios where you will want to use them. Therefore, for the purpose of this article barcode asset tracking and QR code asset tracking can be reviewed together.

Basic Information: What Are Barcodes and QR Codes

Both UPC barcodes (often referred to simply as a barcode) and QR codes belong to the family of barcodes -- a pattern of black and white stripes (1D) or squares (2D) that encode certain information which can be read by a barcode scanner. UPC barcodes can encode only numbers and letters and up to 16 characters. QR codes can fit significantly more information (up to 4,296 alphanumeric characters) and diverse data. This is an advantage compared to the UPC barcodes and gives you more options. For example, consider the following scenario: an asset is lost and a person who found it scans a QR code label with a generic QR code scanner application. You can design QR code in such a way that this person will see the information on your company and where to return that asset. At the same time, when an employee scans the same QR code label on the asset, he will be able to perform work-related functions: check an asset in or out, fill out a form or review asset information. Similarly, a customer scanning QR code on the asset will see information that will be very different from what your technician will see. You cannot do this with a regular UPC barcode.

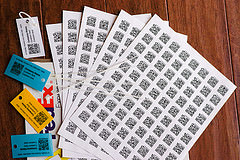

Barcode And QR Code Labels For The Asset Trcking

Some assets may already have a barcode when you receive them. If that barcode has an asset serial number encoded in it, you can use it for the asset tracking. If assets are not labeled, you can easily label them yourself. Your options are:

- Purchase pre-printed QR code / barcode labels

Pre-printed QR code or barcode labels are available in a variety of sizes and materials. As a rule, these labels will contain sequential numbers that you will be able to associate with the assets using an asset management software. You can also order pre-printed QR code asset labels with the assets serial numbers. - Print your own QR code asset labels

You can print your own QR code asset labels using either special label printer or sheet labels and a regular office printer. Many people find it more convenient to use sheet labels to print multiple QR code asset labels at once. A special label printer might be more convenient to use if you need to print just one or several QR code asset labels at a time. As a rule, asset management software that uses QR code / barcode scanning provides an option to generate and print QR code labels for the assets. If it does not, there are several online bulk QR code generators that you can use free of charge or for a nominal fee.

Whether you are purchasing pre-printed QR code asset labels or printing your own, first make sure you know what should be encoded in the QR codes or barcodes. Do not assume that any asset management software will work with any QR code label. Pick the asset management software first, then find out what should be encoded in the QR code / barcode labels that will work with the selected asset management software. Do it in this order and you will spare yourself major headache.

Barcode / QR Code Scanning Equipment For Barcode Asset Tracking

You have the following choices for barcode scanning equipment for the asset tracking:

- Handheld Barcode Scanners

Barcode scanners are the most frequently used equipment, although use of the smartphones for the barcode scanning is rapidly catching up. Barcode scanners need to be either physically or via a wireless connection (bluetooth) connected to a computer. In both cases, barcode scanners can work only in the vicinity of the office computer, and are good for tracking assets in the office or warehouse, but not for tracking of the mobile assets at the remote sites. If you need to track mobile assets in the field, you will need to use either a mobile computer or a smartphone / tablet.

Update. Now you can also purchase barcode scanners that can be connected to the mobile devices (smartphones or tablets) via the bluetooth. A combination of bluetooth barcode scanner and an asset tracking mobile application natively integrated with the barcode scanner provides a good solution for the situation when you need to manage assets in the field, but also need more robust scanning than a smartphone camera can provide. - Mobile Computers

Mobile computers are more sophisticated and expensive equipment. Unlike barcode scanners, mobile computers can use Wi-Fi or cellular data connection to connect to the back-end asset management software. Therefore, they can be used in the field and in the remote locations. Mobile computers also have a screen that allows for the data collection and asset information access. The drawback of the mobile computers is the price - you will need to invest significantly more in the system that supports mobile computers in terms of both hardware and software. - Smartphones and Tablets

You can use regular smartphones or tablets for scanning both barcodes and QR codes. Smartphones have all the advantages of the mobile computers. You can use smartphones to track assets anywhere: in the office, on the job sites, in the field, on the service trucks, etc. With the smartphones you can not only scan QR codes or barcodes on the assets, but also access and record assets information. Built-in smartphone camera allows you to attach an image to the asset transaction; touchscreen allows you to obtain client's signature, and built-in GPS capability can automatcally record a location of the assets transaction. As an additional advantage company employees can use their own smartphones, so you do not need to invest anything in purchasing barcode scanning hardware.

QR Code / Barcode Asset Tracking

Using QR code / barcode scanning for the assets tracking help you eliminate errors and speeds up processing of the assets transactions. Barcodes and QR codes are the most common and the least expensive asset tracking technologies, and it works well in most cases. Barcode asset tracking allows you to:

- Scan in multiple assets when you receive them in the office or warehouse

- Record asset transactions when assets are checked in or checked out by the employees, shipped to a client, returned, sent to repair or undego rotine maintenance or service

- Track and report damages to the assets (reports can be accompanied by the photographs)

- Access a list of the assets in all locations, including office / storage locations, clients sites, or employees

- Track the entire life cycle of each asset, from receiving to disposal

- Perform periodic asset audits using barcode scanning, identify missing or misplaced assets

You might want to look into other asset tracking technologies if you have a high volume asset transactions to process on the regular basis, if you need to track assets that may be out of plain view (e.g. assets on incoming truck, assets that may be inside containers), and if your assets are constantly on the move and you need to map their changing position in real time (e.g. corporate vehicles).

Bluetooth Low Energy (BLE) Asset Tracking

What Is Bluetooth And Bluetooth Low Energy (BLE)

Bluetooth is another wireless communication standard that uses radio waves to exchange information between devices over a short distance. Originally bluetooth was designed for the continuous data exchange, and was used mostly in consumer applications, such as streaming music. This kind of device to device communication consumes a lot of power, and is not practical when only periodic exchange of the small data chunks is required.

Bluetooth low energy (BLE), also known as Bluetooth 4.0 or Bluetooth Smart, was developed with this situation in mind. BLE devices exchange information periodically in the small packets to save power, and remain in a sleep mode in between data exchange sessions. This design resulted in the significant decrease in power consumption while preserving communication range of the bluetooth classic.

Bluetooth low energy started the wide adoption of the bluetooth technology in the "smart" connected devices, also referred to as the Internet of Things (IoT) (that is where Bluetooth Smart name is coming from). Specifically, in the industrial applications bluetooth low energy is rapidly gaining popularity due to its capabilities and lower cost as compared to the other technologies. Bluetooth industrial equipment and devices can be easily controlled from a smartphone. Readings and measurements can be automatically captured by the mobile applications and transferred to the cloud for processing. Bluetooth sensors can provide automatic conditions monitoring and send alerts when conditions are out of range. Finally, BLE beacon technology allows for the real-time assets location tracking, which is significantly less expensive than the other active tracking technologies (commonly RFID for indoors applications and GPS for outdoors).

Bluetooth Asset Tracking Hardware (BLE Tags, Beacons and Receivers)

In addition to the low power consumption, bluetooth low energy supports one to many communication method. In one to many communication method (bluetooth beacon technology), one device (beacon) is periodically sending out information packets, and other nearby bluetooth devices (receivers) can scan for the advertised packets, read and process them. All major smartphones (iOS, Android, Windows) can work as bluetooth receivers. There are also static fixed bluetooth receivers that can be used when the automated asset tracking is required.

Bluetooth tags are in essence BLE beacons that advertise data to the nearby bluetooth receivers. Bluetooth tags can also include sensors that allow you to monitor asset / equipment conditions remotely. The common sensors can monitor asset environmental conditions (such as temperature, humidity, light), as well as mechanical conditions (movements, impact, vibration). Each BLE tag may include sensor(s) for one or several conditions. These sensors allow you to have a 24/7 asset conditions log, and also receive alerts for out of range conditions. You can act quickly on all warnings and prevent costly equipment breakdowns and failures.

In order to read advertising information of the bluetooth tags you need the bluetooth receivers. Bluetooth receiver is a device that can scan for the information packets advertised by a BLE beacon, read this information and send it to the cloud asset management software for the further processing. All major smartphones (iOS, Android, Windows) can serve as bluetooth low energy receivers. There are also static fixed bluetooth receivers that can be mounted throughout the facility for the automated asset tracking.

In some cases, indoors asset tracking systems can also include fixed bluetooth beacons. Fixed BLE beacons are needed to pinpoint the location of a person with a smartphone within the facility. This location can be used for both personnel tracking and asset tracking. In the asset tracking scenario, a smartphone reads bluetooth tags to identify nearby assets, as well as fixed beacons information to identify its own location.

Bluetooth Asset Tracking Methods

You can use bluetooth low energy to track assets in one of the following ways:

- Bluetooth asset tags communicating with the fixed bluetooth receivers. This method is good for the indoor asset tracking without using smartphones or involving company employees. Bluetooth receivers mounted throughout the facility are continuously scanning for the BLE asset tags, and are sending received information to the cloud asset management software for processing. The result is a real time map of the assets location within the facility at any given time. Instead of the isolated bluetooth receivers, you can use a bluetooth mesh - a network of the bluetooth devices that are capable of communicating to each other, and eventially transmitting information to the cloud.

- Bluetooth asset tags communicating to the smartphones. All major smartphones (iOS, Android, Windows) can play a role of the bluetooth low energy receiver,

and scan for the nearby

bluetooth beacons. You will need an asset tracking mobile application installed on a smartphone and running in the background.

The phone itself can be in the employee's pocket, and an employee does not

have to do anything (e.g. scanning) to detect assets location.

Asset tracking mobile application sends detected assets IDs plus its own location to the server. For the outdoor asset tracking a mobile application can use built-in GPS services to determine the phone location. For indoor asset tracking fixed mounted bluetooth beacons may be required for determining a smartphone location. - Barcodes / QR code labels, smartphone and fixed bluetooth beacons. An employee needs to actively use a smartphone to scan QR code or barcode label of an asset that (s)he moves / relocates. An asset tracking mobile application determines the smartphone location by scanning for the nearby bluetooth fixed beacons, and sends information on the scanned assets and locations to the cloud.

Regardless of which method you choose, you will be able to access real time assets location at any given time, in a list format or on the map. In case of the design that inclides the use of the smartphones / an asset tracking mobile application, you will also have the information on which employee handled an asset when.

More information on the bluetooth asset tracking and equipment monitoring is available here.

RFID Asset Tracking

RFID Overview

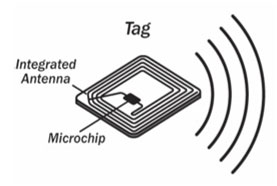

In a broad sense, RFID (Radio Frequency IDentification) is a technology that uses radio waves to detect and identify an object. RFID asset management system

consists of an RFID reader (scanner) and an RFID tag with the embedded chip, antenna, and possibly a battery. RFID tags can be active and passive.

RFID asset tracking system provides significant increase in processing speed as compared to the QR code / barcode asset tracking. Unlike barcode asset tracking,

you do not need to scan each asset individually.

RFID reader will detect all assets within its working range at once. It also can detect assets that are not in the plain view. For example,

RFID reader installed at the gates can scan all incoming and outgoing assets without any human participation. RFID system that includes active tags

can be used to map real time location of the moving assets within the limited distance range.

RFID Tags For Asset Tracking

RFID tags can be active and passive.

Passive RFID tag does not have a power of its own. It "wakes up" only when it appears in the RFID reader working range (around 60 feet maximum)

and sends a signal containing encoded information. The RFID reader receives and decodes information, and sends it to the back-end asset management software for processing.

Information encoded in the RFID tag is stored in a chip. Regular tag can usually store up to 24 characters,

which is enough to encode an asset serial number. There are also RFID tags with the extended memory storage.

Chip and antenna embedded in a passive RFID tag are very small in size, and visually RFID tag may look very similar to a barcode label. Just like the barcode labels,

some RFID tags

can be peeled of a roll and stuck to an asset surface. There are also more durable RFID tags made out of plastic, metal or ceramics, as well as special RFID tags

that can be used on a metal surface.

Pricing: passive RFID tags are more expensive than barcode or QR code labels. RFID tags with the regular memory storage may cost between $0.07 and $0.15.

However you cannot use a regular printer to produce RFID tags for the assets. You need to encode and imprint RFID tags at the same time.

You will need to purchase a special RFID printer which is capable of doing both operations simultaneously, or order pre-printed and pre-encoded RFID tags.

RFID asset tracking system with the passive RFID tags are good for detecting assets and processing of the large volume asset transactions within the single storage unit.

You can check in or out large volume of assets (1000+) in a matter of seconds, while it would take a very long time to scan all of these assets one by one using

barcode or QR code

scanning. RFID reader installed at the location through which assets are passed on the way in and out can perform asset scanning automatically without any human participation.

Active RFID tag has its own battery, and can continuously broadcast its own signal. It also has a much broader (up to a mile) working range.

Since active RFID tag has its own battery it is much bigger in size. Active tag is usually enclosed in a hard casing, and often has external sensors to monitor

environmental conditions (temperature, humidity, etc.) The cost may range from $25.00 to over $100.00, depending on the tag parameters and ability to withstand

harsh conditions.

You need to use active RFID tags for the assets tracking only if you want to map real time asset location within a limited distance range.

These can be your most valuable

assets, or assets that are being moved around and you need to locate them quickly at any given time. While an asset is within the working range of an RFID reader,

the reader will

receive an asset position data and pass it on to the back-end asset tracking system for processing.

Asset Tracking RFID Readers

There is a variety of asset tracking RFID readers on the market that fit different purposes and vary in reading range, style (portable vs fixed),

mobility (USB-connected vs wireless data

connection, such as Wi-Fi or bluetooth), existence of a screen for the data entry and access, and price.

Unlike barcode / QR code asset tracking system, where any barcode scanner can read any barcode, with the RFID asset tracking system you need to

make sure that the RFID reader and RFID tags that you plan to use are compatible. Compatible RFID readers and tags operate within the same

radio frequency and use the

same protocol to communicate.

At this time, smartphones cannot be used as RFID readers, but you can purchase an RFID reader that connects to a smartphone or tablet.

- RFID Asset Tracking Range

Asset tracking range (the distance from which RFID tag can be read) depends on the radio frequency of the tag-reader system (a higher reading range requires a higher frequency), antenna size, and whether an RFID tag is active or passive. Reading range for a passive RFID tag may vary between several inches (low frequency system - LF) to up to 60 feet (ultra high frequency system - UHF) . Reading range for a RFID asset tracking system with the active ultra high frequency tags can reach up to a mile (1,600 meters). - RFID Reader Style

RFID readers can be handheld (similar to a regular barcode scanner), fixed (is installed in one place and reads RFID tags on the assets that are moving past it), and portable (dual purpose - can be ither in a fixed position or handheld). In most cases handheld RFID readers works well, but if you need to automatically track assets that are entering or leaving your facility you will need a fixed RFID reader. - RFID Reader Connection Type

Just as the barcode scanners, RFID readers can either connect to a back-end computer via a USB cable or wirelessly, using bluetooth or Wi-Fi connection. A wireless RFID reader offers an advantage of moving around and away from the computer when scanning assets. Bluetooth RFID reader will allow you to move only a short distance away from the computer (around 30 ft). If you need to scan assets at a longer range, you will need to purchase either Wi-Fi RFID reader, or RFID reader that connects to a smartphone. In a latter case you will also need an asset tracking mobile application that will read data from the RFID scanner and send them to the back-end asset management system for processing. - RFID Scanners and RFID Mobile Computers

RFID readers can work as a scanner (read data and transfer to a back-end asset tracking system, no screen and no option to review or input data), or as a mobile computer. RFID mobile computers work in the same manner as the barcode scanning mobile computers. They have a built-in screen and a keyboard, and allow an employee to review information on the scanned asset, as well as collect data.

A less expensive and more robust alternative to an RFID mobile computer can be a RFID reader connected to a smartphone.

RFID Asset Tracking vs Barcode / QR Code Asset Tracking

RFID technology provides tremendous increase in the assets processing speed when compared to the traditional barcode scanning. Instead of scanning one asset at a time using a barcode scanner, you can scan all assets in the working radius at the same time using RFID scanner. RFID tags do not even need to be on the asset surface. As long as the tag is present, even inside the asset packaging or casing, it can be read.

This speed and convenience comes with a high price. RFID reader can cost anywhere between $500.00 and $2,000+. You also need to purchase the special RFID tags that are more expensive than the barcode or QR code labels, and special RFID printer to encode and print RFID tags. Software and service to put the entire RFID asset tracking system together is also significantly more expensive than a barcode / QR code asset tracking system.

The high price can be justified if the regular QR code / barcode scanning does not work in your situation, for example:

- you routinely process high volume of assets

- you are dealing with the moving assets which need to be tracked automatically at a high speed (e.g. conveyor belt)

- you need to track assets inside casings or containers, where tags are not in a scanner view

- you need to automatically track assets passing through the gates or other fixed location

- assets that you are dealing with cannot be easily labeled (e.g. linens or clothing)

- you need to map assets location in real time within the limited distance range

NFC Asset Tracking

NFC Overview: NFC vs. RFID

NFC (Near Field Communication) uses the same principles as RFID. The difference is that the NFC tag should be much closer to the reader (usually within one inch),

therefore you cannot scan multiple assets at the same time. You do need to scan each asset individually. As with the RFID asset tracking technology,

NFC tag can be on any side of an asset

or even inside a packaging.

All NFC tags are passive (they send information to the NFC reader only when they are in the reader's scanning range, do not have their own power), and have very short

working range. Therefore you can not use NFC technology to map real time assets location, which is possible with the RFID asset tracking system.

You can use NFC asset tracking along with or instead of barcode barcode asset tracking. Using NFC tags intead of barcodes you can increase scanning speed

and still be able to use smartphones for the asset tracking.

![]()

![]()

NFC Tags For The Assets

NFC asset tags are very similar to the passive RFID asset tags. They consist of an antenna, which detects NFC reader and sends information, and a chip that stores encoded data. Antenna / chip combination is very small, and can be embedded in almost anything depending on the situation. You can purchase NFC tags in a variety of materials: plastic tags, disks, sticky labels (including durable, wheather-proof labels), plastic sticky tags, etc. Although you can print information on the NFC tag / label, no printed information is required for the purpose of the assets scanning. All information that is transmitted to the reader is stored on the chip. You need to encode NFC tags so that they contain information you need.

If you want to imprint NFC tags, you will need a special NFC printer that can encode and print information at the same time. If you do not require printed information on the NFC asset tags, you can use NFC scanner capable of writing information to the NFC tags (NFC reader/writer), or you can use a smartphone to do this. Manual NFC asset tags encoding, however, is feasible only for a small number of assets. If you have hundreds of assets to label it will make sense to automate the encoding process using NFC encoding software or NFC printer.

NFC Readers

The situation with the NFC readers is very similar to the barcode scanning -- you can either purchase a stand-alone NFC reader or use a smartphone as an NFC reader. Advantages of using a smartphone as NFC reader are the same as for using a smartphone as a barcode scanner: you can track assets anywhere, use extra functionality available on the smartphones, and do not need to purchase extra hardware. Unlike barcode scanners, which scan faster than smartphones, you do not have a speed advantage for the stand-alone NFC readers: smartphones and stand-alone NFC readers will read NFC tags at about the same speed.

NFC Asset Tracking

If you have a high volume of assets to process daily, if you need an option to track assets in the field and accross multiple locations, NFC is a good choice for you.

NFC technology provides noticeable gain in the scanning speed as compared to the barcode / QR code scanning.

You do not need to focus a reader (scanner) on a tag as you do when scanning barcodes or QR codes.

You only need to touch one asset after another in order to scan them all. And,

as with the RFID asset tracking technology, NFC tags can be inside the asset casing or packaging and not in a plain view.

At the same time, unlike RFID asset tracking system where you need to purchase dedicated RFID scanners, you can use regular smartphones

as NFC readers / writers, so NFC asset tracking system will be significantly less expensive to implement.

GPS Asset Tracking

How Does GPS Asset Tracking System Work?

GPS (Gloabal Positioning System) consists of a system of satellites that are communicating with the receivers on the ground. Receivers (GPS tracking devices) are programmed to communicate with the sattelite system at a preset time intervals, receive an information and recalculate it into the geographic coordinates. Some GPS tracking devices store collected data internally - in this case you need to retreive the GPS device, connect it to the computer and download the asset locations log. Most common and useful are GPS devices which immediately push collected information to the central server, where it can be accessed in real time from any computer or mobile phone or tablet.

In order to implement the GPS asset tracking system, you need:

- A service provider

A provider who owns a server network that will communicate with the assets GPS tracking devices, process information and display it on the map and via reports. - GPS tracking devices

You will need to attach a GPS tracking device to each asset you plan to track.

Unlike previously described system (QR code / barcode asset tracking, NFC asset tracking, RFID asset tracking, bluetooth asset tracking), GPS asset tracking does not require any human participation to track assets: no scanning, recording of the assets transactions, filling out mobile forms, etc.). Once you attached a GPS tracking device to an asset, the tracking starts and continues automatically.

![]()

![]()

GPS Asset Tracking Devices

Although GPS asset tracking devices are sometimes called GPS tags, they are not anywhere close to tags or labels. These are devices, somethat similar to a smartphone in size and appearance, that you attach to the asset you want to track. GPS tracking devices communicate with the GPS system at a regular time intervals, receive a GPS signal, recalculate it in geographic coordinates and either store the geographic position internally or push it to the server for processing. For the real time asset tracking you will normally need a device that pushes data to the server, so that you could monitor real time asset location.

Each GPS tracking device that reports an asset location to the server must be configured to communicate with a specific provider. If you would like to implement a GPS asset tracking system, you would usually select GPS tracking devices from the provider with whom you plan to work. A GPS asset tracking system provider will ship you p the re-configured GPS devices. This works somewhat similar to how your order a smartphone from the Verizone or AT&T and sign up for a data plan. As a rule, you will pay a fee for each GPS device itself, and then a monthly fee for each trackable asset - similar to how it works for the smartphone plans. On average, you can expect to pay anywhere between $10.00 and $100.00 per each GPS device, and $5.00 to $30.00 per asset for the monthly service. (Notice that GPS asset tracking prices vary significantly, you might want to take this into account when shopping for the GPS asset tracking provider.)

GPS Asset Tracking System

GPS asset tracking stands apart from the other asset tracking systems (barcode / QR code, NFC, RFID, Bluetooth) and is used for a somewhat different purpose. All of the above asset tracking systems track assets location in terms of the business units (e.g. office, room, job site, service truck, warehouse) - geographical position is not that important and may change in case of the service truck. GPS asset tracking system tracks only geographical position of an asset. Unlike barcode / NFC / RFID / Bluetooth asset tracking systems, GPS asset tracking system tracks asset location continuously and automatically, without any human participation. Barcode / NFC / RFID / Bluetooth asset tracking systems track assets transactions history (where and how an asset was used over its life cycle), while a GPS asset tracking system tracks assets path and changing of its geographical position.

As a result, GPS asset tracking is commonly used for the moving assets (such as vehicles), shipping containers, valuable assets and in the other situations where geographical position and path of an asset must be tracked in real time. If your primarily goal is to track assets location, life-cycle transactions and usage history, you need to use a different asset tracking technology -- barcode, QR code, NFC, RFID or Bluetooth.

If you are not in the position to implement a full-blown GPS asset tracking system (perhaps due to a necessity of a significant investment or if your assets are not suitable for attaching the GPS tracking devices to them) the workaround can be a QR code asset tracking system that uses a smartphone as a scanner. Smartphones have a capability to determine the current GPS location and send it to the cloud asset management system. You will just need to ask your employees to scan a QR code on the asset to determine the geographic location of an asset.

Which Asset Tracking Technology Is Best For Your Business - Takeaways

When deciding which asset tracking technology will work best for your business, you can use this general rule of thumb:

Barcode / QR Code Asset Tracking

This is the least expensive and easierst to implement method, and it works well for any situation where your main goal is to organize assets, make sure you know where each asset is at any moment, be able to track assets movement history and periodically audit assets to identify if something is missing or misplaced. Specific business scenarios may include:

- Tracking work tools -- tracking who takes a tool, when is it returned and in what condition, checking where tools are and how they are used.

- Tracking expensive audio-video and electronic equipment - tracking expensive equipment that employees are borrowing for a job.

- Tracking rental equipment -- tracking assets and equipment that is rented out or leased out to customers. It can be anything from IT equipment to events management equipment to heavy construction equipment.

- Property management asset tracking -- tracking assets in rental units: which asset is in what unit, which assets are not returned, missing or broken after rental ends, assets inventory.

- Tracking of assets circulating between office and remote / customer locations -- may include containers that are sent to customers and are returned when empty, testing equipment installed at homes during inspections, beer kegs tracking, loaned demo equipment tracking, assets tracking at construction sites, etc.

- Tracking of office and IT equipment -- tracking of office computers and other IT equipment, assign equipment to employees, perform audits to check for misplaced or missing assets.

- Asset tracking in storage and logistics - tracking of client's assets that are temporarily stored in your warehouse and / or returned or shipped to a client.

NFC asset tracking can be used instead of or along with the QR Code / barcode asset tracking if you need to process large volume of the assets fast. If your regular

asset transactions (such as receiving new assets, processing rental returns, etc.) may include 50+ items you will save significant time by processing

these transactions faster using NFC asset tracking system.

You can also use NFC scanning only for a part of the assets that require it, and QR code / barcode scanning for the rest.

NFC asset tracking is only slightly more expensive than the QR code / barcode asset tracking. The cost increase is due to the fact that the NFC tags are more expensive,

and you need to outsource the tags production

or purchase a special NFC printer.

RFID asset tracking system is much more expensive to implement than barcode scanning or NFC systems. In addition to the RFID asset tracking software and service fee,

you will need to purchase a lot of dedicated hardware:

RFID scanners, RFID printers, possibly RFID mobile computers if you need to track assets outside of the office.

Update. Using bluetooth RFID scanners connected to a mobile device will decrease RFID system expenses and will allow for the asset tracking in the field. You will need to use software with a

native support for the attached bluetooth RFID scanners. QR Inventory android application

provides such capability.

Some situations where the RFID investment is warranted are:

- Tracking of the very high volume of assets.

- Tracking of the assets inside the containers or packaging.

- Automatic tracking of assets passing through a checkpoint (e.g. conveyer belts, people carrying assets through the gates, etc.).

- Assets that are not suitable for labeling, such as linens or clothing that need to be washed on a regular basis.

- Requirement to discover and map real time asset location within a limited distance range (requires active RFID tags).

Bluetooth low energy asset tracking is well suited for the automated asset tracking indoors and outdoors, and is gradually replacing RFID asset tracking. BLE asset tracking has very similar capabilities to RFID, but is less expensive and more versatile.

Unlike RFID systems, bluetooth asset tags can be read by all major smartphones. And BLE tags equipped with the sensors allow you to remotely monitor asset conditions and quickly act on the warning signs (increased temperature, vibration, etc.), preventing equipment breakdowns and failures.

GPS asset tracking makes sense only if your goal is to continuously monitor real time geographical position of an asset, restore an asset path during any given time interval and make sure that an asset is staying withing the set boundaries. It is a very specific purpose, and it is different from the broader asset tracking goals (tracking asset locations, transactions, life-time history and usage, auditing assets) which can be achieved by using other methods: QR code / barcode asset tracking, NFC or RFID asset tracking, or BLE asset tracking.