Digitizing Field Operations With Mobile Forms

Digitizing field operations means converting all field paperwork into the digital forms and checklists for the field data collection.

Field technicians can fill out digital forms and checklists on the mobile devices: smartphones, tablets or mobile computers.

Once digital forms are completed, they are submitted to the cloud, where the data are processed and are made available to the authorized personnel via reports.

Reports can be accessed online via a secure web dashboard, or downloaded in a format of the user choice: csv, pdf, txt, etc.

Using QR Mobile Data software you will be able to

digitize all types of the field paperwork using custom or ready to use mobile forms.

Read More

Blockchain Traceability For Manufacturers And Food Processors

The problem with implementing traceability, especially for the small manufacturers and food processors, is the amount of time and paperwork it requires. And even if the company puts it's best effort into

the traceability program, it is impossible to trace the final product back to its origin through the multiple supply chain partners and their internal isolated traceability systems.

Combination of mobile and blockchain technologies solves this problem. Mobile data collection allows companies to easily collect data and track products on the shop floor in real time.

Blockchain technology, or other solutions based on the blockchain principles, allow all supply chain partners to record and review traceability information in one system.

Traceability information for each component, product batch and assembly is

added by the respective companies as product progresses through the supply chain, and the entire supply chain network has an immediate access to this information and can act on it.

Read More

Bluetooth Asset Tracking And Internet Of Things (IoT) BLE technology is multi-purpose. BLE tags equipped with the sensors can not only help you track assets location, but also provide 24 / 7 monitoring of equipment and asset

conditions (temperature, humidity, light, vibration, etc.). You can configure and receive automatic alerts if conditions are out of the specified range, and

act fast to fix small problems before they become much bigger problems.

Bluetooth low energy (BLE) is developing fast and is gaining popularity in the industrial setting.

One of the applications of BLE technology in the industry is asset tracking and equipment monitoring. Using bluetooth low energy beacons and / or receivers,

bluetooth tags and / or mobile devices you can track assets indoors and outdoors. Depending on your needs and budget, asset tracking can be automatic (no human participation required),

or semi-automatic (involves participation of people with mobile devices).

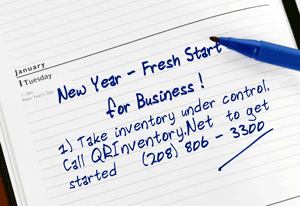

Effective Real Time Inventory Management: Common Inventory Problems And Solutions

In the last several years that we are offering QR Inventory - a mobile inventory system with real

time inventory tracking -

we had identified the most common inventory and assets related problems that companies are facing.

Many of these problems are not directly addressed by the traditional inventory management systems. This article is a summary of these situations and

solutions offered by QR Inventory. If you need to manage out-of-office assets and inventory in real time and cannot find an acceptable solution, read on. See if you

have one or more of the problems listed here, and if so, how QR Inventory can help you solve it (or them) and manage inventory efficiently.

Read More

Barcode System For Mobile Inventory: Making A Barcode Scanner Work With An Inventory Management Mobile Application

Mobile devices (smartphones and tablets) are perfect for managing inventory and tracking assets on site in real time.

Normally you would use a smartphone or tablet camera for barcode scanning. However, scanning with a smartphone camera has its limitations.

If you need a more sophisticated scanning option, you can use a handheld barcode scanner connected to a mobile device (iPhone, android phone, iPad, android tablet).

This article discusses different ways of connecting a barcode scanner to the mobile devices, pluses and minuses of each approach, and how you can use a connected barcode scanner with

your inventory management mobile application.

Read More

Barcode Inventory Management, Shop Floor Data Collection For Manufacturing: Case Study

Using mobile devices (smartphones or tablets) on the shop floor for barcode scanning, data collection and look up, filling out mobile forms greatly improves manufacturing process efficiency.

This case study discusses how Ionex Research Corporation, a manufacturer of high-performance process filtration and treatment equipment, streamlined documentation of the manufacturing process, stock control and traceability

with the smartphones and QR Inventory software.

Read More

Mobile Forms, Data Collection Linked To The Business Workflow

What can your business gain by switching from your current data collection methods to the mobile forms? How can you incorporate mobile forms data collection into the business workflow?

This article gives you an overview of what mobile forms are, what are their advantages and what is involved in implementing mobile data collection for tracking your business operations.

Read More

Inventory Traceability: Lot Number Tracking With QR Code Scanning

How QR code scanning, smartphones, mobile forms and the cloud can help you achieve end-to-end inventory traceability in a simple and efficient manner.

Read More

Mobile Asset Tracking Technologies: Barcodes, QR Codes, NFC, RFID, Bluetooth Beacons, GPS Tags

How do mobile asset tracking technologies (barcodes, QR codes, NFC, RFID, Bluetooth, GPS) work and which one to use for your business.

Read More

Top 7 Applications Of Mobile Asset And Inventory Management

How mobile devices (smartphones, tablets) can help you control business assets and inventory, and in what situations using mobile devices for asset and inventory tracking makes most sense.

Read More

Tips On Making Physical Inventory Count Fast & Error Free

Use smartphones for inventory scanning and data recording, and you will do physical inventory counts in a fraction of a time it used to take, with less resources and higher accuracy.

Read More

Mobile Devices, QR Codes Streamline Stocktaking, Asset Audits For Small Businesses

If you need to do inventory count or asset audit on a regular basis, you know how much headache it can cause, from a necessity to close down business to incorrect results that don't match.

QR Audit software takes this headache away by automating inventory control and audit accounting tasks. It allows businesses to complete physical inventory count / fixed asset audits in hours rather than days or weeks.

Employees take stock by scanning inventory or assets with a smartphone, and send scanned batches directly to the cloud-based central database. Scan based entries and uninterrupted data pipeline ensures fast audits and

accurate results.

Read More

Tips On Tracking Mobile Assets & Inventory In Multiple Locations

If you have mobile assets and inventory in multiple locations it may be challenging to accurately track everything.

You need a number of users in different remote locations, away from the office computers to be able to enter and access data in real time.

Having a system that combines mobile application (to collect and access information in the field)

with a cloud based back-end for storing / distributing data can be a good solution. See how it may work!

Read More

Using NFC for Asset Tracking & Inventory Management

QR Inventory now supports NFC tags. NFC reading is much faster than QR code scanning, so if you need to process high-volume asset or inventory transactions using NFC tags will save you a lot of time and money.

Read More

Asset Management: Labeling & Entry Using Smartphone & QR Code Scanning

New feature of QR Inventory simplifies new assets entry in out-of-the-office locations. You can label an asset, scan a label,

fill out information, take photos if needed and upload data to the server - all by using a smartphone.

Read More

Inventory & Asset Management Software Selection: Types & Trends

Inventory management and asset tracking software has evolved from desktop to online cloud systems to mobile software running on the tablets and smartphones.

Barcodes are beeng replaced with qr codes, barcode scanners and mobile computers - with the mobile phones. NFC based inventory and asset tracking is gaining popularity.

This article provides an overview of inventory management trends to make the process of picking the right software system easier for small businesses.

Read More

Bulk QR Code Generator For Your Assets, Equipment, Properties

This free tool allows you to generate QR codes for your equipment, assets or properties, customize label template and bulk download ready-to-print QR Code labels.

Your clients and / or employees can submit service request, report damage or problem by scanning QR code on the label with a smartphone and filling out a form.

Read More

How Mobile Forms and QR Codes Improve Field Operations Efficiency

Implementation of mobile forms for field data collection, coupled with QR code / barcode scanning capabilities speeds up the process,

eliminate double-entry, errors and information loss, and creates uninterrupted real time data exchange between field technicians and the office.

Once such systems were available only to the large companies due to

their price tag. Now advent of smartphones and tablets made it affordable for business of any size to switch from paper forms to mobile data collection.

Read More

How To Generate And Use Dynamic QR Codes

What are dynamic QR codes: how are they different from static QR codes, how you can generate and print them and how you can use them for

field service operations: equipment maintenance, property management, asset tracking and inventory management.

Read More

QR Inventory v2: One Software To Manage Assets and Inventory

After accumulating customers' comments for a little bit over a year we recently rolled out version two of QR Inventory software. The new version

differentiates between assets and inventory, providing different workflow for each type, allows for different location types and seamless transfer of

assets and inventory between them, and improves your ability to define what information to store, show, track, record and report using granular

custom types and properties.

Read More

Barcode Scanning Equipment For Asset & Inventory Management

Barcode scanners vs QR code / smartphone combination vs mobile computers for inventory and asset management - overview of

barcode scanning equipment questions from Q&A sessions.

Read More

Mobile Asset Tracking and Maintenance

How QR codes and smartphones help keeping your records in order and assets well maintained

Read More

Smartphones As Smart Barcode Scanners For Asset And Inventory Tracking

Kill not two, but three birds with one stone - track assets and inventory using barcode scanning,

automatically map assets locations,

take photos and attach

them to inventory transactions. All using just one device - smartphone running iOS or Android.

Read More

Tips On Inventory Barcoding / Assets Tagging / Initial Stock Taking

Barcoding and initial stock taking for inventory and assets can be time consuming and is prone to errors. The article discusses

how to streamline this process using smartphone and QR Inventory mobile application.

Read More

AHG, Inc. Partners with Intacct to Connect Mobile Inventory Management with Accounting and Finances.

Integrated QR Inventory - Intacct solution gives businesses an option to tie mobile, QR and barcode - based inventory and asset tracking to cloud financial management / accounting.

Read More

Guide to Managing Assets and Inventory Using Modern Technologies

Tips and practical advice on how to implement inventory management and / or asset tracking system using modern technologies,

such as qr codes, mobile applications and smartphones.

Read More

New Module of QR Inventory Optimizes Asset Tracking For Small Businesses

New Asset Tracking & Circulating Inventory module of QR Inventory software makes it easy for businesses to track assets and inventory

which are constantly moving between warehouses, job sites, service vans and employees or clients. Authorized employees can record transfer of an asset

with one scan of QR code, and information becomes immediately available to central database and all authorized devices. The result is: no more wasted

time and money, no lost items, increased productivity.

Read More

Benefits of QR Codes, Barcodes For Inventory and Asset Tracking

New options in inventory management and asset tracking software, such as ability to use smartphones for

processing transactions by scanning qr code / barcode on the item, should make small businesses move away from spreadsheet-based inventory management....

Read More

QR Inventory Lite Streamlines Asset and Inventory Tracking for Small Businesses

Small businesses which find traditional inventory management systems too complex and expensive now have an alternative - QR Inventory Lite.

This simplified version of QR Inventory software replaces manual inventory entry with inventory transactions based on barcode or QR Code scanning.

Instead of maintaining inventory spreadsheets employees can use their smartphones to process inventory transactions with one scan....

Read More

Automation of Asset Tracking, Inspections with QR Codes and a Smartphone

Some ideas on how you can use QR Codes and a smartphone to track assets and equipment, streamline equipment service procedures,

speed up and simplify

inspections and audits, and even enhance safety....

Read More

QR Inventory Reinvents Inventory Management For Small Businesses

New technologies, such as mobile applications and QR codes, are changing the way small businesses are approaching business tasks.

These technologies, built into productivity software, allow small businesses to optimize and error-proof business operations. QR Inventory, a new small business

inventory management application, use these technologies to help businesses streamline inventory management process without invenstment in proprietary hardware...

Read More

Use Of QR Codes or Barcodes and a Smartphone for Efficient Inventory Management

QR Codes were not invented for marketing and advertising. QR codes were invented by Toyota subsidiary for managing large number of components that could not

be accommodated by regular UPC barcodes. Now, when smartphone applications are added to the mix, businesses with much smaller inventory can benefit from

managing inventory using QR codes and smartphones. It not only saves money on the hardware, but provides mobility and flexibility....

Read More

Mobile Applications in Business Blog Home

Recent Posts: